From garage to global impact – Machine manufacturers’ growth story over 3 decades

SME Inspirations

337 week ago — 6 min read

Enterprise: Grind Master Machines Pvt. Ltd.

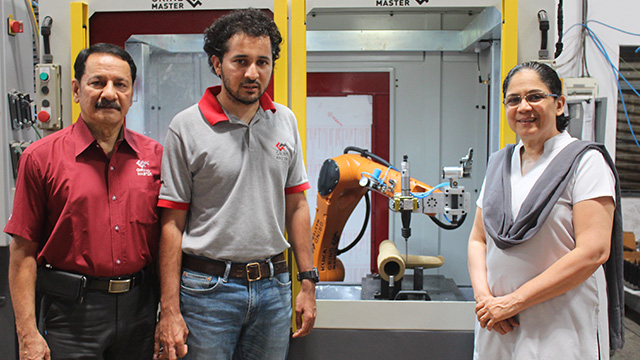

Founders: Milind and Mohini Kelkar

Year it was founded: 1984

Sector: Manufacturing

Location: Aurangabad, Maharashtra

Successful enterprises are built on a vision. Mohini Kelkar and Milind Kelkar, in 1984, dreamed of creating a ‘special purpose machines’ manufacturing facility that would have a global impact. Grind Master was the result of their endeavour. Today, the production facility sprawls over 250,000 sq. ft with 300 employees and their products are sold in China, Europe and USA. Sameer Kelkar, their son, is the second-generation entrepreneur who is now using his experience of studying in IIT Mumbai and UC Berkeley to add value to the company as it continues on its path to growth. Competing as they do with German and Japanese companies is no easy task, but Grind Master looks up to the challenge of fulfilling their promise of evolving to the ‘absolute’. They have in the past and continue to provide innovative solutions in the form of tools and machinery in the automotive, appliances and steel manufacturing industries among others. In 2012 the firm diversified into robotic automation and has been developing exclusive robotic technologies.

In conversation with GlobalLinker (GL) Mohini Kelkar (MK) shares the journey of Grind Master.

GL: Tell us about your business.

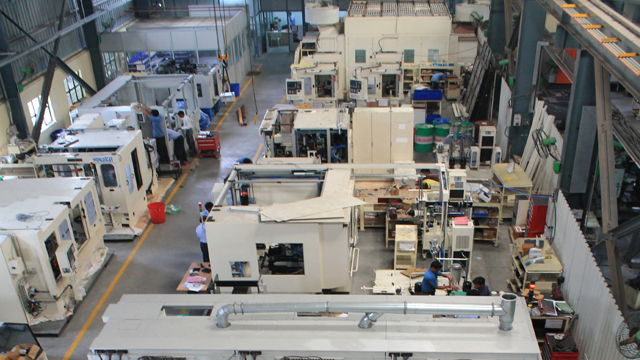

MK: Grind Master was started in 1984 by my husband and myself. We are both Production Engineers from VJTI Mumbai. With modest beginnings in a garage, Grind Master is now an Indian multinational with operations in China, Europe and USA. The main manufacturing facility is in Aurangabad, spread over 250,000 sq. ft. area and 300 employees.

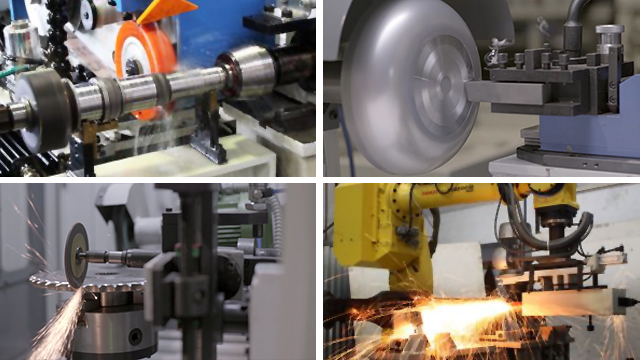

We observed that deburring, grinding, polishing operations were done manually by the manufacturers of appliances, auto parts etc. The imported equipments available were very expensive and unaffordable by Indian industries. We therefore developed several concepts and manufactured machines for the Indian market to begin with. Over a period of 30 years, Grind Master has developed a very wide range of machines and has a large customer base in automotive, appliances and steel manufacturing industries within India and abroad.

Our collaborations with several partners throughout the world has made technology exchange possible and greatly contributed to our growth. We started exports to China in 2009 and today more than 50% of what we produce is exported to China. These high technology machines for microfinishing crankshafts and camshafts perform the operation of maintaining size and stringent surface finish requirements. These machines are sold in competition with German and Japanese Companies. We have now a wholly owned subsidiary in China.

Our son Sameer Kelkar who is IIT Mumbai graduate and MS in Robotics from UC Berkeley University in California joined our business in 2011.

Grind Master started its robotic automation business in 2012. Since then we have been working on developing exclusive robotic technologies like handling of hot jobs, precision deburring of critical parts. Since 2015, we have been working on robotic automation for foundries. The fettling and deflashing of castings is extremely hazardous process in foundries. We are one of the very few companies worldwide who offer robotic automation for these processes. For these innovations, we have also received CII National award in 2017.

In 2017 we acquired a company in France for getting better foothold in European markets.

We have constantly pushed the boundaries of ideas and technologies. As a part of our eternal quest to be the best that the industry has to offer, we continue to evolve to the “absolute”.

GL: What are the challenges you have faced in establishing your business?

MK: Since we are in the business of manufacturing special purpose and customised solutions in metal finishing and deburring, innovation and design thinking is extremely vital. To scale up our operations we had challenges in getting suitable manpower and then grooming them. Another challenge we faced for going global was the image India had in the machine tools and automation space. Of course, now with the advent of IT, the situation is lot better. Our approach has been to collaborate with worldwide companies and this gives us access to the latest in the world as well as helps us known worldwide for our innovations.

GL: What is the USP of your business?

MK: Our USP is ‘Absolute engineering to build solid solutions that exceed customer expectations with the motto ‘Can and Will’. We wish to create a culture of enduring excellence.

GL: What is your big business dream?

MK: Our dream has been to create a global impact in our field.

GL: What is your message to aspiring entrepreneurs?

MK: Innovation and passion are the keys to success for any venture.

Network with Mohini Kelkar by clicking on the 'Invite' button on her profile.

Disclaimer: This article is based solely on the inputs shared by the featured member. GlobalLinker does not necessarily endorse the views, opinions & facts stated by the member.

Posted by

GlobalLinker StaffWe are a team of experienced industry professionals committed to sharing our knowledge and skills with small & medium enterprises.

Network with SMEs mentioned in this article

View GlobalLinker 's profile

SME Inspirations

Most read this week

Trending

Comments (2)

Please login or Register to join the discussion