Industrial IoT vs SCADA

Digital & Technology

230 week ago — 6 min read

Everywhere we look, there is some form of supervisory control and data acquisition (SCADA) system on which the whole industrial work is dependent.

An automation control system that provides insights to supervisors about the plant conditions is SCADA. It is used in all industrial sectors to gain access to the entire plant from a control room.

The Industrial Internet of Things (IIoT) brings together brilliant machines, advanced analytics, and people at work. It’s the network of industrial devices connected by communications technologies that can monitor, collect, exchange, analyse, and deliver valuable new insights like never before.

The future of industrial automation has been evolving in such a way that robots are now replacing people. And now is the time for an extraordinary revolution with the introduction of the Industrial Internet of Things and Industry 4.0

Also read: The development of the Industrial Internet of Things

How IoT took over SCADA

SCADA, no doubt, is the most relevant technology for industry 4.0. But the limitation of SCADA is the absence of a connected ecosystem.

IoT is a game-changer when it comes to the ecosystem. Its intelligent capabilities are highly adaptable to modern industries today. Industrial IoT has emerged as software that is applied in contrast to SCADA. With the implementation of this disruptive technology, conditions like scalability, data analytics came into existence.

Also read: 8 big data trends to invest in 2020 and the years to come

Four key differences between industrial IoT and SCADA

The Industrial Internet of Things has played a unique role in enhancing the functions of remote monitoring. While most companies have already implemented SCADA systems for this purpose, the Industrial Internet of Things has gradually replaced its functions. Let us evaluate the contrast between the two systems.

- Device interconnectivity

When implementing SCADA systems, unifying devices created by distinct manufacturers is a close to impossible task. Additionally, when the same manufacturer develops the devices, it can be challenging to use them interchangeably as their model may vary. They also require a horizontal program that can function across a host of devices, irrespective of their producer or model.

Now when we evaluate IIoT, the system depends on the notion of interconnectivity. The primary motive of this is to facilitate communication across numerous devices. Nothing is dependent on the model or maker of the appliances. It uses procedures like MQTT to reduce direct communication over all devices in a comprehensive system.

- Operating expenses and costs

To store extra data in a SCADA system, companies will inevitably incur costs on new servers. In software licensing or obtaining additional features, SCADA users have to buy special licenses for new services and pay to upgrade the system frequently.

The Industrial Internet of Things can significantly mitigate hardware and software costs for businesses while also removing the requirement of physically enabling software licensing and upgrading by implementing cloud services.

- Data insights

While using SCADA systems presents shortcomings in analysing and interpreting historical data, companies tend to experience these hurdles in analysing old data and solving it. SCADA does not focus on collaborating or interpreting the data that businesses churn out daily. The information neither brings any valuable insights to the users nor offers any crucial help to the business's decision-makers.

In this area, IIoT outshines its competitors in this area. It consolidates and collects data from several business functions and then applies big data analytics to predict efficiency and avoid any potential fluctuations. With definitive acumen from the IIoT, corporations can expect unforeseen equipment hindrances and maintenance requirements.

- Scalability

Some devices present critical information in SCADA software but have never been utilised as they require an overhead expense. As the number of users increases, the bandwidth should also be made large enough to handle the growth, causing security concerns, and mitigating most issues. Furthermore, it also takes a long time to set up.

IIoT can bring in and process large amounts of data while also enabling users to connect additional appliances at ease. All of this data is sent to a cloud and accessed using login details. Information and data from anywhere in the world can be viewed and accessed via an HMI system that connects them to the clouds.

After comparing and evaluating the two subjects discussed in the article, it is clear that utilising the benefits of IIoT would be beneficial in the long run.

What does the future hold after a relative analysis?

Conclusively, both SCADA and IoT involve sensors and data acquisition. They do differ in many aspects but share a common goal. SCADA is not a full control system, whereas the Industrial Internet of Things is made up of many devices connected. It helps to control objects remotely across different networks and architecture.

Also read: 10 reasons why your business should adopt IoT

To explore business opportunities, link with me by clicking on the 'Connect' button on my eBiz Card.

Image source: shutterstock.com

Disclaimer: The views and opinions expressed in this article are those of the author and do not necessarily reflect the views, official policy or position of GlobalLinker.

View S Gangadhararao 's profile

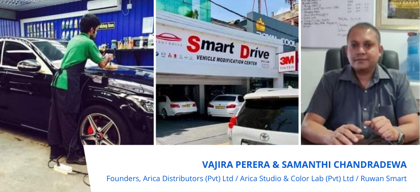

SME Inspirations

Other articles written by S Gangadhararao Boppana

208 week ago

Importance of automation in industrial process

222 week ago

Most read this week

Comments

Share this content

Please login or Register to join the discussion